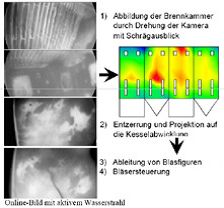

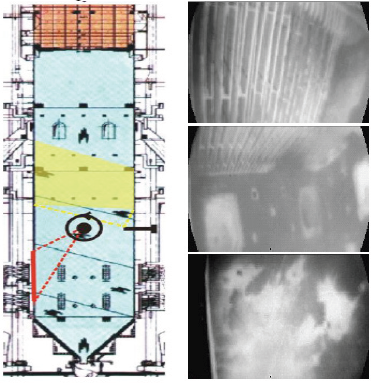

Monitoring and Diagnosis System

Furnace Monitoring CCTV

- - Monitoring system for slag formation and combustion state inside

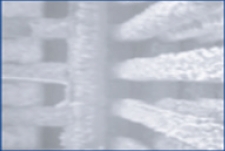

boiler through high temperature CCTV - - Condition of boiler tube have a great effect on the boiler

operation and efficiency - - It avoid slag and efficiency of heat exchange, need high class

cleaner to check the heat distribution inside boiler. - - It improve the generating efficiency through real-time monitoring

inside furnace - - It can observe the inaccessible area inside furnace by another

equipment - - It can observe the damage of tube for particular area

- - If encounter a system problem for Soot-blowing, it is possible to

operate and control efficiently - - If encounter a serious problem for boiler tube, it is possible to fix

quickly