Products Information

CX-200 is provides early detection information before serious problem happen through online monitoring about rotating machinery condition, and protects the manufacture facility through various diagnosis.

Also maximize manufacture production efficiency and maintain the quality through prediction of the life cycle.

Various signal input is available such as vibration, current, temperature, pressure, RPM, and it is convenient to use the all of functions like system set up, data acquisition, signal processing, real-time monitoring, alarm-monitoring, precise diagnosis, degradation prediction by customer.

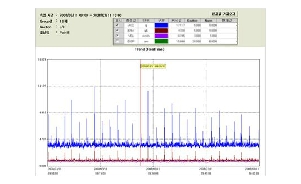

For your convenience monitoring, on the left of the program of the systems overall structure and the status of each channel (normal/caution/alarm) to check real-time, the class structure is located.

You can perform system analysis more efficiently through real-time trend, time, spectrum, screen to screen and a complex combination of the screen on your screen to display multiple channels at the same time, also multi-window support current analysis plot as a dB-scale, it can perform effectively by providing information window including cursor information.

Various cursor and zoom function used at analysis each window added that optimized automatic fault diagnosis algorithm, therefore from beginner to expert are easy to analyze.

We can provide customers special set and stable system.

Through continuous upgrade, we also manage quickly our customer needs.

To cope with customers request in specialized fields, we can provide stable system in a quick time.