Products Information

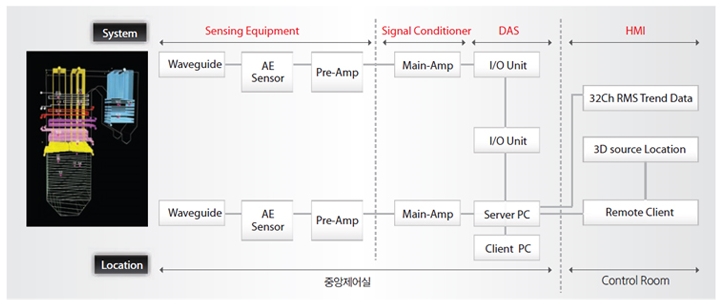

Boiler Tube Leak Detection Systemis performed for occurred tube leak and crack for superheater, reheater, coal cutter, water cooled wall on main boiler of thermal power plant. This system have in accordance with acoustic emission inspection in one method of non-destructive test during operating for power plant on real time monitoring.

And leak location have provided by 3D and then, it is possible to shorten for maintenance time and increase maximum efficiency for electric operating alike. This system is possible to get early occurred leak time and detect for leak than existing system. It have advantage quickly maintenance by provided point of 3D of leak position.